Best viewed using:

Internet Explorer

or

Mozilla Firefox

Bending tubing without collapsing or kinking it

There are two different methods that work well for bending (forming) the various sizes of our stainless steel tubing. Bending with internal support, and bending with external support.

Internally supporting tubing during bending:

In most situations our tubing can be cold-formed (bent) without damage providing some form of tubing wall support is part of the bending process. Annealing (softening) should only be required if extremely tight radius bends or complex shapes are needed. For further information on annealing please click here.

.018" Tubing:

We have successfully cold-bent the .018" diameter tubing over a 1/16" diameter mandrel. This produces an "after spring back" bend of about 10 N-Scale inches which seems small enough for most electrical conduit work, street lights, and general lighting applications. After forming, microscopic inspection showed no evidence of surface cracking either on the extension (outer) or compression (inner) surfaces.

In this test, we used internal tubing wall support by sliding our (N2112) .012" diameter stainless wire inside the tube prior to bending. Once formed, removal of the wire is best accomplished by pulling the wire through a .012"-.014" slot cut in a scrap piece of brass, aluminum or other sturdy material. Allow the tubing face to butt up against the far side of the slot, then pull the wire through using pliers. Doing it this way puts all of the stress on the tubing face and eliminates the possibility of accidentally distorting the tubing shape you've just so carefully created. Only gentle support of the tube is required during this "extraction" process. Alternately, if you don't have a hobby saw that will produce a .012"-.014" sawed slot, tightly clamp two pieces if scrap material in your favorite vise so that there is a gap between them that the .012" wire will slip in but the tubing won't. Make sure they're clamped tight. If you're performing bends of much larger diameter than 1/16", the stainless wire can probably be reused.

It is likely that bends tighter than the 1/32" radius (1/16" dia.) we performed would successfully cold-form as well, but keep in mind, the sharper the bend, the harder it becomes to pull out the support wire. Trial and error will tell for sure.

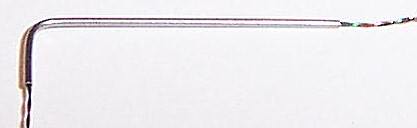

After our test above, we easily threaded a twisted-pair of our red/green #38 magnet wire up and around the bend by simply pushing the wire. See figure 1 below. If we had flared the tubing end first, we could slide on a lampshade, solder on an LED and this would look great sticking out of a building over a door.

Figure 1

In figure 2 below, is an example of bending the 0.018" tubing around some .062" pins in a fixture to form tubing for a gooseneck building lamp. Here's the .012" wire would be pulled out while the tubing remains in the fixture with the pins in place to support the tubing shape while the wire is removed. In this example some of the pins are removable so they can be inserted as the bending process progresses.

Figure 2

Externally supporting tubing during bending:

For our tubing with outside diameters of 0.025" through 0.050" we have found an easy method of bending that produces beautiful bends and is a one-step process. All of you familiar with electrical conduit tubing benders that Electricians use, know that the conduit is supported by flanges that support the sides of the conduit, so when it is bent, the conduit doesn't collapse or deform. For lack of a better description, we will call our method the bolt-thread bending method (clumsy, but descriptive).

This bending method produces very satisfactory results but is limited to specific bend radii and tubing diameters. To better describe what we mean, two pictures are certainly worth a thousand words (or a few hundred at least).

Figure 3

Figure 3, above is a typical cross-sectional magnified view of bolt or machine screw thread as defined by SAE (Society of Automotive Engineering) since about 1948. The only things of importance for our discussion is thread pitch, and thread depth. The 60º thread angle is constant for all bolt sizes and thread pitches.

Since the thread walls are at a 60º angle and spiral around a bolt shaft, they offer a nice support for several sizes of our tubing if it were rolled around the thread while being held into the thread for support (to prevent deformation like the conduit bender does). Figure 4 below show a clearer picture of this.

Figure 4

As long as the tubing is held firmly into the threads, it will be supported and its round shape will be maintained perfectly (we have done this many times and it looks beautiful).

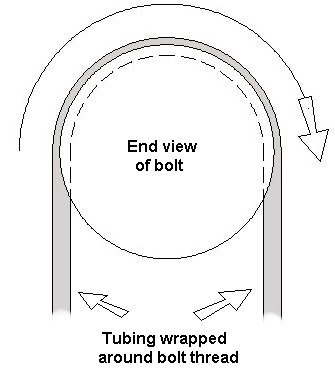

Figure 5 below shows a side view (bolt end view) of this for clarity. In this case the tubing was bent around 180º to form a "U" as would be used for the top of a curved-neck streetlight.

Figure 5

This process has the added advantage that wire for the LED wiring can be placed inside the tubing prior to bending. This makes threading wires through tubing much easier.

The one downside of this bending method is that the various different bolt diameters and thread depths are a limiting factor for tubing sizes and bend radii. Figure 6 below shows the two extremes that would not produce satisfactory results.

Figure 6

The tubing on the left is too large in diameter to get proper support from the bolt threads during bending (or the threads are too close together and the thread depth insufficient).

On the right, the tubing is too small to make it easy to hold down into the threads while wrapping it around the bolt diameter for the bend (or the bolt is too large for the tubing being used).

As a result, these factors do limit the use of this method to a certain range of tubing that will fit different bolt diameters and thread combinations. Fortunately, several of our tubing sizes, and several different bolt diameter/thread combinations do work very well for some of our applications, but predominately in the larger scales (HO, S and O). For the smaller tubing and tighter radii bends, the internal support for tubing bending method at the top of this page continues to be the most versatile.

Bending mandrels with radius-bottomed grooves for different sizes of our tubing and different radius bends is something we are considering for manufacture, but at this time other projects are taking a higher priority. For the time being, the bolt-thread method should work well enough to get the job done.

© 2020 Ngineering