Best viewed using:

Internet Explorer

or

Mozilla Firefox

Pre-wired NK8064B & NK8064BL Gas Welder Kits

Video files require time to download, so please be patient.

Click anywhere on the picture below to start the video of a repair job being done with a gas torch on a Caterpillar road grader.

Watch for the torch ignition and startup sequence, followed by the subtle color changes during welding. This video was shortened for easier downloading (actual length of welding cycle is ~ 35 seconds).

Utilizing the industry’s smallest

microcontroller and associated voltage control circuitry, these modules

with LED,

consume less than

20 ma. This

makes all of the NK8064B

Kits well suited for low power applications such as battery operation but can

easily be powered by any well-filtered and regulated DC power source with an

output of 6-18VDC. The very small overall size of this module will allow it to

be easily placed in and around any structure.

Connecting

the NK8064B:

Installing the NK8064B is very straightforward. Because the module has circuitry on both sides, care must be taken to be sure that the components or wire solder points will not make contact with any metal object which could cause a short

This kit is pre-wired with

input power wires already connected. The red wire is for connection to +DC and

the black wire is for connection to –DC (ground). These wires are pre-tinned for

easy soldering to your power source.

Figure 1 below shows a close-up of the circuit and wiring connections. Point 3,

4 & 5 are the outputs that connect to the attached LEDs with approximately 6

inches of very tiny #38 insulated wire. Care must be taken not to kink these

wires during installation

Important note:

A low-wattage iron with a pointed tip should be used for connection of wires. Too much heat or solder can easily damage the wires.

Figure 1

Connecting theNK8064BL:

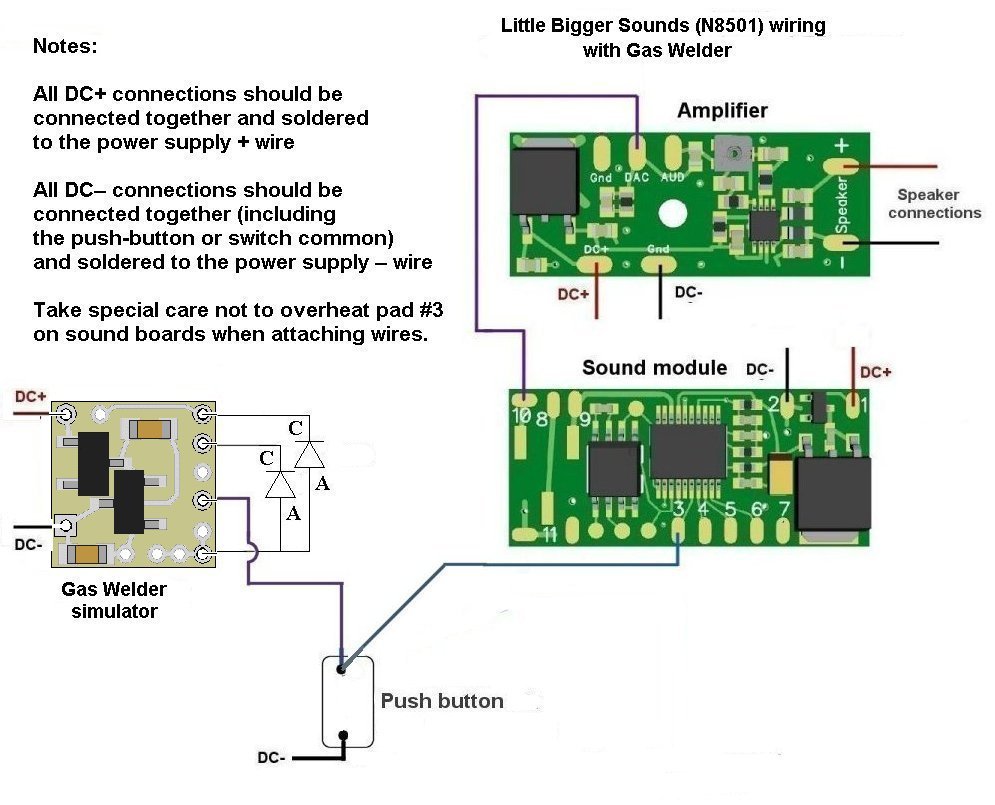

The NK8064BL includes the addition of a latching function that starts the lighting effect by grounding the violet wire connected to pin 6 and is timed to start the N8301-092 or N8501-092 Gas Welding sound effect (sold separately). See Fighre 2 below.

If the sound module being used is a N8301-092 (Little

Sounds without the external amplifier) the connections wound be the same between

the sound board and the welding Simulator.

Figure 2

This grounding can be easily achieved by simply connecting (thru a push button) to a common –DC power connection. An example of this is shown in Figure 3 below. In this example, the N8501-092 (Little Bigger Sounds) version of the sound effect is shown.

Figure

The LEDs

included with this kit will provide sufficient brightness for a realistic

effect. The brightest light output will be seen from the front of the LED

surfaces, but these LEDs do also have relatively bright “side-shine” allowing

good viewing over a horizontal angle of up to 150 degrees. Plan the positioning

of the LED in your model to “point” them toward the middle of the viewing angle

for best effect.

We recommend

mounting the LED from the back by attaching adhesive to the wires near

the back of the LEDs so adhesive is not placed directly on the LED. It

is also recommended that whatever adhesive is used that it does not

contain high aggressive solvents that could attack the insulation on the

wires. Walthers Goo is an example of an “aggressive” solvent type

adhesive. Elmers white Glue, CA (superglue) and 2-part epoxies are very

safe for this type of mounting and will not damage wires or surfaces of

your model in most cases.

If the LEDs are to be mounted next to a scale figure such as a person kneeling while

welding, place the LEDs at the point where you wish to have the arc flicker

appear and route the wires away from that position. The wires are tiny and can

be easily hidden. Also, the wires can be painted if required as long as acrylic

paint (non-solvent paint) is used.

We hope the

added realism it provides enhances your enjoyment of the hobby.

© 2024 Ngineering