Best viewed using:

Internet Explorer

or

Mozilla Firefox

N8131 Assembly and installation

Connecting the N8101 & N8101B:

Using the N8101 is very straightforward. Its tiny size will allow it to

be placed nearly anywhere.

Solder points #1 and #2 are the power

input connections. Power input to the N8101 can be up to 16-volts and can be

up to 25-volts for the N8101B, and can

be either analog DC, DCC. AC voltage can also be used but

is limited to the RMS equivalent value. Solder point #3 is

–DC output (or ground), and solder point #4 is +DC output. See figure 1.

Figure 1

Also included on the board is solder point #5. This is an optional connection point provided for +DC resisted voltage output to a polarity sensitive device such as an LED. Figure 2 below shows the back side of the board.

Figure 2

Shown

are the two solder pads provided for either an 1/8-watt or 1/4-watt

surface-mount type resistor. When a resistor is installed, the circuit

through to solder point #5 is completed so the resistor is in series with

the +DC output #5. Connecting a device such as an LED between #5 and #3 will

provide power for the LED.

Note: For proper LED operation, resistor

selection must be calculated based on maximum expected input and LED

voltage. If

you need help

to determine proper

resistance, please go here.

When connecting an LED to the module, proper polarity must be observed. LEDs are “polarity sensitive” and will not function if connected backwards. Connect the LED cathode (the – connection) to point #3 on the module and connect the LED anode (the +) to solder point #5.

Important

note:

A low-wattage iron with a pointed tip should be used for connection of

wires. Too much heat or solder can easily damage the wires, or the module

and void its warranty.

Also, all wires should be

pre-tinned before soldering them to the N8101. This will make connection

quick and easy and ensure excessive heat is not applied to any solder

points.

Flicker control:

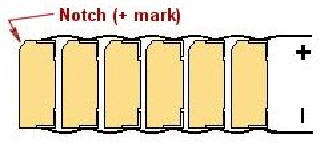

Included in this package are tantalum polarized capacitors.

Tantalum capacitors are superior to other polarized capacitors because they

have a larger storage capacity for their size and do not “age” like other,

electrolytic polarized capacitors do. In modeling where small scale factors

dictate available space, these little jewels can be very useful for storing

an electrical charge and releasing it when input power is momentarily

interrupted. In model railroading, dirty spots on the track are a common

source for tiny power interruptions.

Polarized capacitors have a plus DC connection, and a minus DC connection.

By wiring them in parallel (all pluses connected together, & all minuses

connected together), their storage capacities (uf, or microfarads) are added

together.

NEVER

wire them in series with each other (end to end).

Because of their “boxy” shape and tiny size, they can be stacked

strategically to utilize the least amount of space possible. These

capacitors have a stripe and an angle at one end that identifies the plus

(+) DC connection. Figure 3 below shows an example of 6 capacitors stacked

and soldered in parallel. You can use the #26 solid wire in this package for

that purpose.

Putting it all together:

Since the capacitors are DC devices, they cannot

properly function with any other

type of input voltage. As a result, they

must be connected

“behind” the N8101/B DC Power Source module at

the output solder points

3 &

4. Input from

the track pickups connect to solder point

1

&

2.

See figure 1 on the

front of this instruction

for more detail.

We recommend using the two 4” segments of #32 black super-flex wire for

connections to points 1 & 2, because this wire is designed for repeated

flexing and can easily withstand the rotation of trucks on rolling stock

as they negotiate curved track. This flexing is what this wire is

designed for.

The red and black #32 hook-up wire can be used to connect the N8101/B

output solder points

3 & 4

to the capacitor “bank” connections, then on to whatever device(s) you

will be providing power to. Simply just cut these wires into whatever

lengths work for your project and strip and tin their ends before

attaching them to the N8101/B or the capacitor bank. Figure 4 below shows

a typical wiring diagram for connection of one of our Lighting Effects

Simulators.

© 2021 Ngineering