Best viewed using:

Internet Explorer

or

Mozilla Firefox

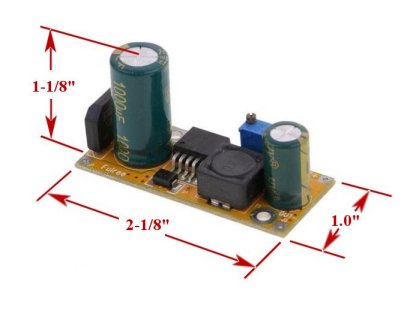

Note: The height dimension is from the board bottom surface to

the top of the large capacitor. An additional 1/8" space under the

bottom should be allowed for clearance of soldered component leads that

are clipped off and protrude below the board bottom surface. Two mounting holes

are provided and spacers or small fiber washers can be used to elevate the board

so the clipped protruding leads cannot touch any mounting surface

Alternately, double-sided sticky foam mounting tape can be used providing the

foam thickness is at least 1/8" and the adhesive is a high-strength bonding type

that will not easily come loose.

The picture below shows the bottom side

of the circuit board for reference. If the mounting holes are to be used, the

easiest way to properly locate the holes is to simply set the circuit on the

surface to be mounted and mark through the holes using a pen or pencil. These

marks can then be drilled in the mounting surface for screws and nuts or

self-tapping screws depending on the application.

© 2018 Ngineering