Best viewed using:

Internet Explorer

or

Mozilla Firefox

Connecting the Early-era Schoolbus flasher w/stop sign flasher

Utilizing

the

one of the

industry’s

most advanced

microcontrollers

and

highly regulated

voltage control circuitry, this

total module consumes less than

40ma of current during normal operation with all LEDs attached. Input DC voltage

range is 5.6 to 20 volts.

Preparing the N8110-06:

The module’s

tiny size

and thin construction will allow it to be placed so it is easily hidden from

view. The module has circuitry

both sides so care must be taken when mounting to prevent

contact with metal (electrically conductive) material which could cause a

short circuit. The bottom of the circuit board can be used for mounting with the

small square double-sided sticky foam pad that is included.

Important

note:

A

low-wattage

iron (15-watt or less) should be used for this process and a needle type

pointed tip should be used for connection of the

wires

to the module. Too much heat or solder can

damage the wires,

LEDs

&

module and void warranty.

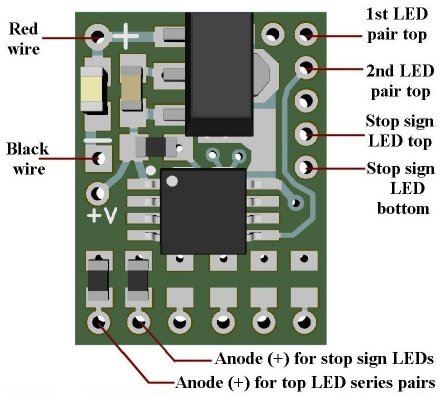

Figure 1

below shows a detailed view of the wires to be connected as viewed from the

front side of the circuit board.

Figure 1

Soldering wires to the module:

The red and

black power wires should be stripped and tinned prior to attachment to the

circuit module. Strip approximately 1/4” of insulation from each end of each

wire and ensure the wire strands are twisted together and carefully tin each

end.

Each wire’s

tinned end should be inserted into the appropriate solder point

with the wire inserted from the front side of the board and soldered on

the back side of the board. For this process, good lighting, magnification, and

a method to hold the circuit while soldering will be very helpful in the

positioning of the wires.

Extra care must be taken when soldering wires in position.

Because of their close proximity, excess solder can easily cause bridging

between pads.

For best

success in soldering the wires,

place each wire into the appropriate solder hole and seat the insulation up

against the hole on the front side of the board. Ensure the wire is held in that

position when applying any flux and

solder to the hole on the back side of the board.

It is easiest if a small amount of solder is placed on the soldering iron

tip first, then the wire is placed in position and flux is applied

at the back side of the hole. While holding the wire in position, touch

the tinned wire strand and the hole with the soldering iron tip allowing the

solder to flow into the hole capturing the wire. This soldering process should

only take about 1/3 of a second to provide a clean shiny solder joint with no

excessive solder. Then, carefully snip the protruding wire from the solder

joint. This will ensure a good joint and eliminate possible shorting. Repeat

this process for all remaining wires.

Soldering

the LED wires to the module requires the same care as outlined above. If the LED

wires are single-strand magnet wires, ensure they are properly stripped

and pre-tinned

prior to soldering them in place.

Testing and mounting the assembly:

The N8110-06

Simulator assembly is now completed and should be tested prior to installation.

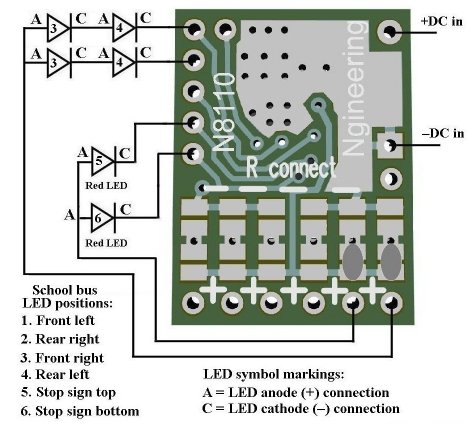

Figure 2 below shows a schematic view of LED connections.

NOTE: This

module DOES NOT HAVE

reverse polarity power protection, so be extra careful when connecting the

+DC RED

wire and the –DC BLACK

wire to your power source. Connecting the backwards

will damage the module.

Once power

has been applied and all LEDs appear to be function normally, the assembly can

be mounted into your project.

Included in this package is a small double-sided sticky foam pad for this

purpose.

Figure 2

This completes connection of the N8110-06 module. We hope you enjoy the added realism our module provides.

© 2021 Ngineering