Best viewed using:

Internet Explorer

or

Mozilla Firefox

NLD8110-03 Dual-Marslight Simulator Effect and Installation

Description of Lighting Effects

This

NLD8110-03 provides a tiny,

low-voltage/low-current circuit which produces a dual

Marslight simulation that runs for two 20ma

white family (white, incandescent, yellow-white, golden-white) LEDs

in simultaneous operation.

All solder connections explained below

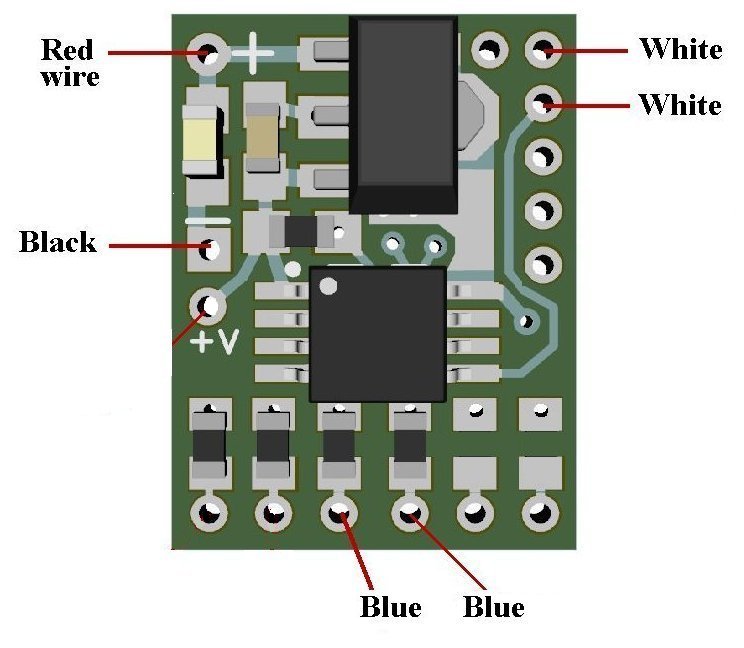

Figure 1

NLD8110-03 (DCC/RC) input power connections:

The NLD8110-03 Simulator is

configured for DCC environments and sound decoders having 3.3-volt

accessory functions. Since track polarity is not a factor in DCC the

need for DC polarity protection is not required. Also, in an RC

modeling environment, battery power is known so this is not an issue.

However, since this family of

Simulators

doesn't have polarity protection, care must be taken during wiring to

ensure polarity is correct before power is applied. Otherwise, the

circuitry

will be damaged.

Figure 1 above shows a detailed view of the locations of the wires to be

attached as viewed from the front side of the circuit board. These wire

are included in this package.

Utilizing the

one of the

industry’s

most advanced

microcontrollers

and

highly regulated

voltage control circuitry, this

total module consumes less than

40ma of current during normal operation with all LEDs attached. Input DC

voltage range is 3.4 to 20 volts.

Preparing

the

NLD8110-03:

The

module’s tiny size

and thin construction will allow it to be placed so it is easily hidden

from view. The module has circuitry

both sides so care must be taken when mounting to prevent

contact with metal (electrically conductive) material which could

cause a short circuit. The bottom of the circuit board can be used for

mounting with the small square double-sided sticky foam pad that is

included.

Important note:

A

low-wattage

iron (15-watt or less) should be used for this process and a

needle type pointed tip should be used for connection of the

wires

to the module. Too much heat or solder can

damage the wires,

LEDs

&

module and void warranty.

Figure 1 above shows a detailed view of the locations of the wires to be

attached as viewed from the front side of the circuit board. These wire

are included in this package.

Soldering wires to the module:

Each

of the six wires should be stripped and tinned prior to attachment to

the circuit module. Strip approximately 1/4” of insulation from each end

of each wire, ensure the wire strands are twisted together and carefully

tin each end.

Each

wire’s tinned end should be inserted into the appropriate solder point

as shown above, with the wire inserted from the front side of the board

and soldered on the back side of the board. For this process, good

lighting, magnification, and a method to hold the circuit while

soldering with be very helpful in proper positioning of the wires.

Extra care must be taken when soldering these wires in position.

Because of their close proximity, excess solder can easily cause

bridging between pads.

Soldering wires to the module—continued:

For best success in soldering the wires,

place each wire into the appropriate solder hole and seat the insulation

up against the hole on the front side of the board. Ensure the wire is

held in that position when applying

any flux and solder to the hole on the back side of the board.

It is easiest if a small amount of solder is placed on the

soldering iron tip first, then the wire is placed in position and flux

is applied at the back side

of the hole. While holding the wire in position, touch the tinned wire

strand and the hole with the soldering iron tip allowing the solder to

flow into the hole capturing the wire. This soldering process should

only take about 1/3 of a second to provide a clean shiny solder joint

with no excessive solder. Then, carefully snip the protruding wire from

the solder joint. This will ensure a good joint and eliminate possible

shorting. Repeat this process for all remaining wires.

Again,

a

low-wattage

iron

(15-watt or less) should be used for this process and a needle type

pointed tip should be used for connection of the LEDs to the wires.

...A shameless promotion...

Should you not have the soldering tools necessary to perform the

previous steps, our 12-watt N40M2 soldering iron with the N408I tip is

perfect for these operation and we also have N4200 low-temperature 2%

silver solder and N4500 no-clean liquid soldering flux for easy

soldering...

Testing and mounting the assembly:

At

this point, the NLD8110-03 Simulator assembly is completed and should be

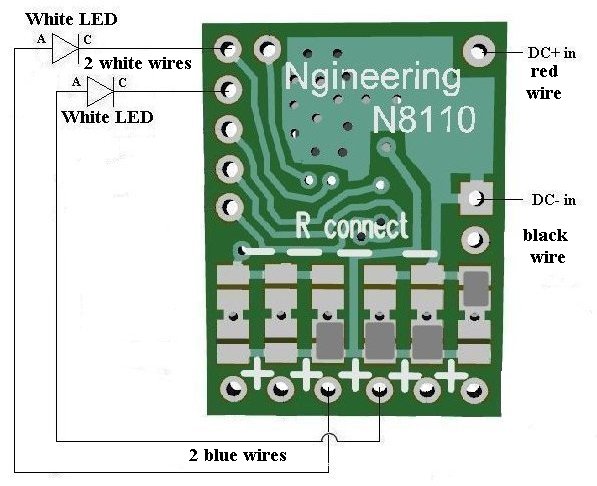

tested prior to installation. Figure 2 below shows

red and black wires soldered on the right side of the circuit

(rear view). These two wires are for power input and should be connected

to your power source.

REMINDER:

This module DOES NOT HAVE

reverse polarity power protection, so be extra careful when connecting

the +DC RED

wire and the –DC BLACK

wire to your power source. Connecting the backwards

will damage the module.

Once

power has been applied and all LEDs appear to be function normally, the

assembly can be mounted into your project.

Included in this package is a small double-sided sticky foam pad.

Peel one of the protective backings off of the pad and stick it to the

bottom side of the module. The foam will help electrically insulate the

module from contact with any metal parts.

LED

symbols shown indicate “A” (anode +DC) & “C” (cathode –DC) connections.

Figure 2

This completes connection of the NLD8110-03 module. It is recommended that a thorough re-inspection of all connections and module placement be performed prior to applying power to your model. We hope you enjoy the added realism our module provides.

© 2025 Ngineering