Best viewed using:

Internet Explorer

or

Mozilla Firefox

Working with our .004" Straightened stainless Wire

Our .004 "diameter straightened wire is tiny, but it's very easy to work with. A clean working environment, bright light, good magnification and the proper tools are all that is required. Since this wire is heat-treated to a spring temper, it can withstand normal (reasonably careful) handling and will maintain straightness.

Characteristics for modeling considerations

Since this wire can be applied to a virtually endless variety of applications in modeling projects, below are some useful tidbits about its behavior:A 6" length will maintain vertical straightness without support and will freely return to position if flexed (an example of a long free-standing antenna).

A 2-1/2" length will maintain straightness (no droop) at horizontal position and will return to position if flexed.

A 9" length freely suspended (no anchoring) between two vertical edges 8-1/2" apart droops 7/8" below straight. This is the natural (gravitational) effect due to its weight. This "droop" effect can be eliminated or enhanced by anchoring the wire ends. Since this wire has a break-strength of more than 4 lbs., tight anchoring is not a problem.

This wire can be used to form springs for various low-force applications. It is 304 stainless steel of the highest quality with spring-temper and has excellent "memory" characteristics.

Bending

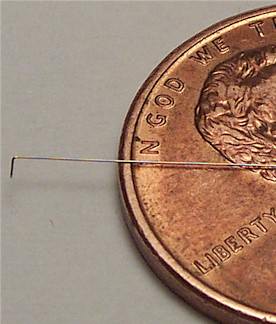

This wire can easily be formed into any desired shape. It is spring-temper, so when forming, "over-bending" is required to compensate for spring-back. Sharp 90 degree bends can be made without concern about breakage or significant reduction in strength. However, repeated bending at a single point should be avoided to prevent metal fatigue. Below is an example of a 90 degree bend we made using standard needle-nosed pliers:

Annealing

If very severe bending or wrapping is desired (creating an anchor loop, for example), this wire can easily be annealed to a dead-soft condition. Use a lit candle or simply a match, and heat the portion of the wire you want to anneal to a cherry-red color and allow to air-cool. Do not over-heat (white-hot color) or you will degrade its composition and destroy its mechanical properties. Only heat the wire long enough to bring it to "color", then remove the heat source.

Below is an example where we annealed about 1/2" of the wire end, wrapped it around a 1/16" rod, then wound it around itself 4 times and snipped-off the excess. Add a tiny drop of CA or epoxy to the wound area and it would make an excellent anchor loop that would withstand considerable tension (about 4 lbs.). A much smaller loop could be just as easily formed.

Bonding

Since this wire is stainless steel, it cannot be soldered successfully. There have been claims of soldering stainless with some degree of reliability using acid flux and high-content silver solder, but all indications are that it is hit-and-miss at best.

For all non-structural (appearance only) bonding CA adhesive, 5-minute epoxy, etc. work just fine. They will form a good bond providing the material is clean and dry. Isopropyl alcohol with an air dry will work well in most cases. If there is any possibility that oils or grease may be present, lacquer thinner is a good choice. Be sure and use it in a well ventilated area and note that it is extremely flammable.

For the strongest possible bond, the best structural adhesive we've seen is Cyanopoxy® by Cool Chem. This is a two-part (or 3-part with primer) system that bonds dissimilar materials at the molecular level. Truly amazing stuff, you can even bond rubber to Teflon! It's not cheap, but well worth the investment if you need super strength.

For structural joining, it's best to anchor through holes in material or form loops as above. These can usually be hidden from sight if desired.

Painting

As with most materials, if they're clean and dry, paint will adhere. This is true for stainless steel as well. It can be brush or spray painted, but because of its very smooth finish, paint will scratch off if abraded.

© 2008 Ngineering