Secure Site

Shop with

Confidence

Best viewed using:

Internet Explorer

or

Mozilla Firefox

Connecting the NLA/D8050, NLA/D8051 or NLA/D8052 Custom Simulators

Installing either the NLA/D8050, or NLA/D8051, or NLA/D8052 is very straightforward. Its tiny size and thin construction will allow it to be placed in many spaces too small for even the smallest Z-scale decoder. Because the module has circuitry on both sides, care must be taken to be sure that the components or wires soldered will not make contact with any metal object (such as a locomotive frame) causing a short circuit.

Included with the module are two 6” lengths of #32 insulated wire. If necessary, these can be used for power input wires.

NLA8050, NLA8051 and NLA8052 (analog) input power connections:

The NLA8050-52 Simulators are configured for analog (DC) operating environments. They will function normally with track voltages ranging from 3.2 to 16-volts DC. The circuit includes a Schottky barrier diode to protect the module from reverse input voltage polarity. This means when it is wired the normal "engineer's side is the +DC track side", the effect is fully operational. when running in reverse "fireman's side is the +DC track side) the effect is not in operation. For many lighting effects, this will not be a problem because they are intended for forward operation.

For those effects that need full bi-directional operation, one of our N8101 DC Power Source circuits can be added in front of the effect simulator board to eliminate DC polarity issues. The N8101 contains a very-low voltage-drop Schottky bridge rectifier which will slightly raise the startup voltage threshold of the lighting effect by about 0.2-0.4 volts. Figure 2 below below is schematic diagram of the connections required.

All solder connections explained below

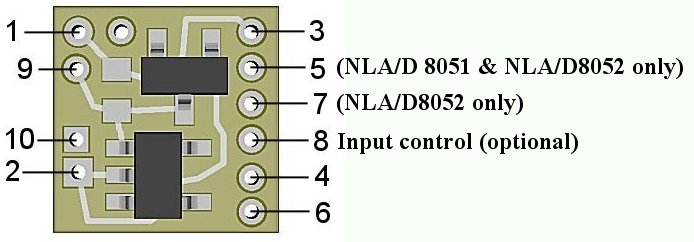

Figure 1

Figure 2

NLD8050-52 (DCC/RC) input power connections:

The NLD8050-52 Simulators are configured for DCC environments and sound decoders having 3.3-volt accessory functions They have an on-board jumper in place of the barrier diode used in the analog version. This allows them to operate fully at 3.3-volts (even slightly, below allowing for LED brightness). Since track polarity is not a factor in DCC the need for this protection is not required. Also, in an RC modeling environment, battery power is known so this is not an issue. However, since this family of Simulators doesn't have polarity protection, care must be taken during wiring to ensure polarity is correct before power is applied. Otherwise, the circuitry will be damaged. Figure 3 below shows the front side of the NLD8050-52 with the jumper installed and the barrier diode not installed.

Figure 3

In a DCC environment, most wired decoders have a blue wire which is the common connection for all wired functions (F0, F1, etc.). It is the + DC connection and will be connected to solder point #1 as shown in Fig. 1.

If the decoder is a “drop-in” style without wires, consult the decoder manual and use the blue wire supplied to connect point #1 to the appropriate + solder pad.

If the solder pad has a resistor in series with it, be sure to connect the blue wire behind the resistor (see Fig. 4). This will ensure full voltage is supplied to the module.

Figure 4

Important note: A low-wattage iron with a pointed tip should be used for connection of wires. Too much heat or solder can easily damage the wires, decoder or module and void the warranty.

Also, all connecting wires should be pre-tinned before soldering them to the module. This will make connection quick and easy and ensure excessive heat is not applied to the solder points.

Next, choose the function you want to control the NLD8047 module and connect the appropriate function wire to solder point #2. For example: If you want F1 to turn on the Simulator, connect the green wire to #2.

Again, if the decoder is the drop-in style, use the enclosed green wire to connect the appropriate function solder pad to #2. Make sure the pad chosen for this connection is not a “+” pad , but a function pad (– DC connection).

Whichever function you choose, make sure it is programmed for On/Off control only. Do not program the function for special effects. The NLD8050-52 will control the special effects.

Connecting LEDs

When connecting the LEDs, proper polarity must be observed. LEDs are “polarity sensitive” and will not function if connected backwards. The NLA/D8050 is configured to allow the connection of one (1) 20mA LED, the N8051 up to two (2) 20 ma LEDs, and the N8052, up to three (3) 20 ma LEDs. Since these simulator modules are custom programmed, the on-board resistor will be of the appropriate value to support the type (color) of LEDs for each custom application. If additional (off-board) resistors are required, they will be included with the packaged module along with a wiring diagram for that particular application.

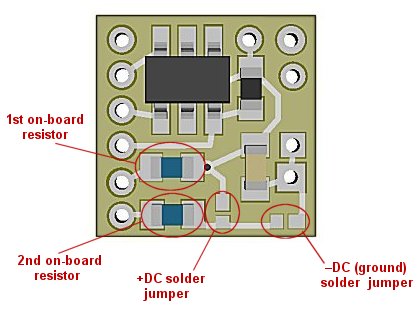

Unlike our traditional Simulators, these new low-voltage modules have two on-board current limiting resistors. The second resistor can be connected either to the circuit's +DC voltage or to it's –DC (ground) by solder jumpering either of two pairs of jumper pads on the rear-side of the module. Figure 5 below show the location of the resistors and solder jumper pads. Never place solder on both pairs of jumper pads, this would destroy the Simulator. See Fig. 5 below.

Figure 5

Depending on which version Custom Simulator (1 output, dual output, or triple output) the second on-board resistor may or may not be required, and possibly a 3rd off-board resistor may be needed. If this is the case, the extra off-board resistor will be supplied with the products and either the individual instruction sheet (supplied with product), or an emailed wiring diagram will be supplied for the customer's unique circuit requirements.

It is important to use wire appropriate for the size of the LEDs and their placement in the particular application. In most cases, our N5038 magnet wire will work very well and can be easily hidden from view. connect the LED cathode (the – connection) to point #3 on the module and connect the LED anode (the +) to solder point #4. Again, this LEDs will use the on-board current limiting resistor so it can be wired directly.

Once again, be sure to use a low-wattage soldering iron when connecting wires to the module. Our N40M2 12-watt Iron with either the N408I (iron clad) Needle Tip, or the N408X (bare copper) Needle Tip would be an excellent choice for this operation (or any DCC decoder work).

Input control

Solder point 8 on the simulator module is for connection of an (optional) input control wire. This additional control can be connected to either a momentary throttle function such as F2, or any on/off decoder function (F1, F3, F4, etc.). This simulator can handle either type of control input. If an on/off function is selected for hookup, be sure the decoder has any special effects turned off for that function. The simulator module will take care of the effects.

For non-decoder installations or for analog operation, solder point 8 can be connected to any switch (momentary pushbutton or magnetic reed switch) which is tied to -DC (ground).

Flicker control

Another new feature we've added to our low-voltage Simulator modules is solder-points for direct wiring of external capacitors for flicker control. These are solder points 9 and 10. When connecting external capacitance for this purpose, if multiple capacitors are used, they must be wired in parallel (all + connections together, and all – connections together). They must have a voltage rating of 16-volts or greater. The + (plus) connections are to be wired to solder point 9 and the – (minus) connections wired to point 10.

© 2014 Ngineering